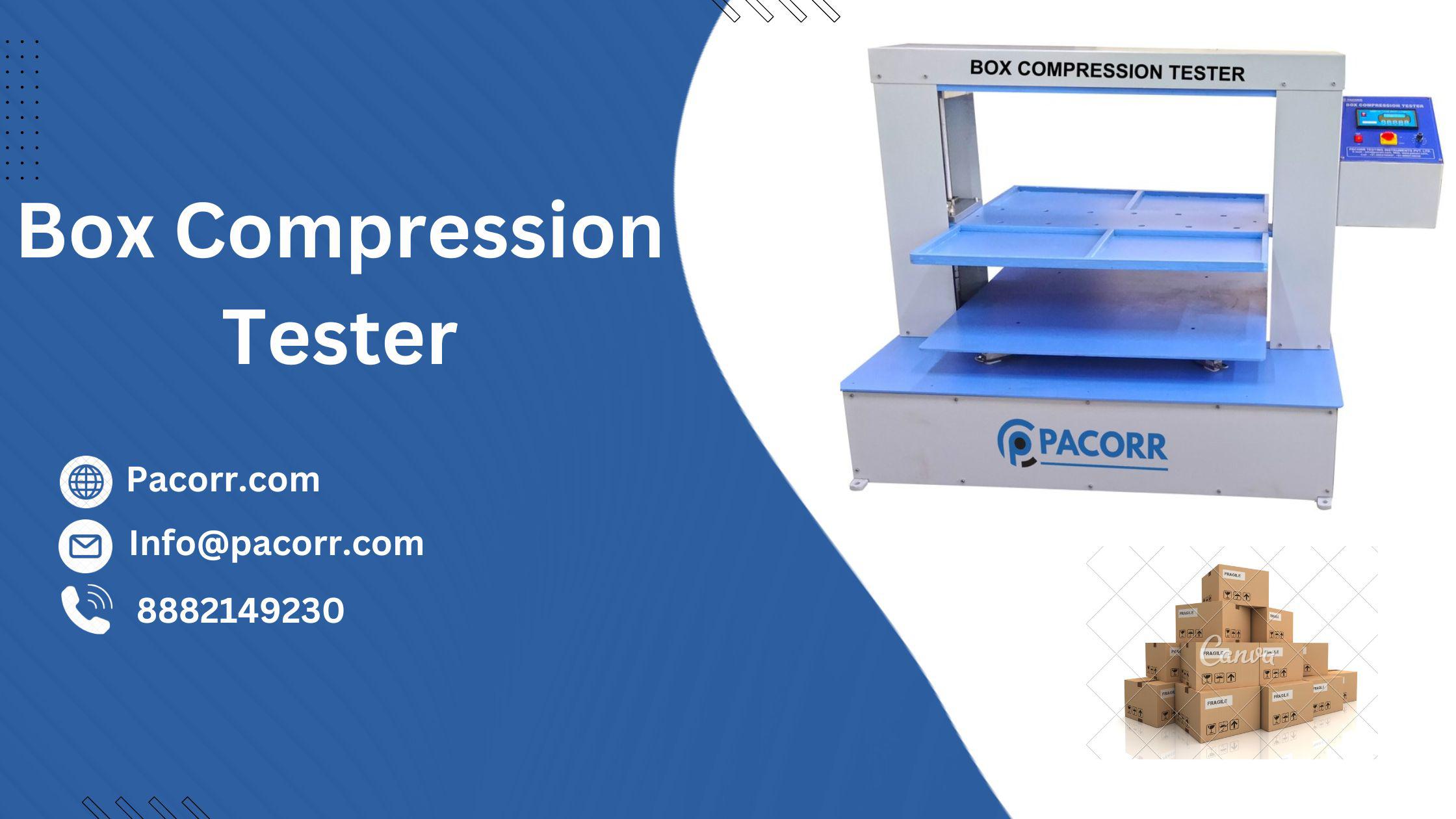

Packaging is a critical aspect of product distribution, ensuring that goods are delivered to consumers in perfect condition. One of the essential tools in packaging testing is the Box Compression Tester. This instrument is vital for determining the strength and durability of boxes, ensuring that they can withstand the rigors of transportation and storage. This article explores the function of the Box Compression Tester, its benefits, and why it is a crucial investment for manufacturers.

What is a Box Compression Tester?

A Box Compression Tester is a device used to measure the compressive strength of packaging materials, particularly corrugated boxes and cartons. The test determines the maximum load a Box Compression Testing can endure before it collapses. This data is crucial for manufacturers to design packaging that can protect products effectively throughout the supply chain.

How Does the Box Compression Tester Function?

The operation of the Box Compression Tester is straightforward yet highly effective. A box is placed between two plates; one is stationary while the other applies pressure. The tester gradually increases the load on the box until it reaches its breaking point. The force required to crush the box is recorded, providing valuable information about its structural integrity. This process helps manufacturers gauge the box’s capacity to bear weight, which is essential for ensuring that the contents remain secure during handling and transport.

Why Box Compression Testing is Essential

- Product Protection: Packaging must be robust enough to protect products from damage during shipping and storage. By using a Box Strength Tester, manufacturers can ensure that their packaging is capable of safeguarding the contents under various conditions.

- Meeting Industry Standards: Different industries have specific requirements for packaging durability. Box compression testing helps ensure compliance with these standards, guaranteeing that the packaging meets the necessary safety and performance benchmarks.

- Cost Efficiency: Understanding the compressive strength of packaging allows manufacturers to optimize material usage. This can lead to cost savings by reducing the amount of material needed while still providing adequate protection.

- Maintaining Brand Image: Damaged packaging can lead to dissatisfied customers and harm a brand’s reputation. Reliable packaging, verified through compression testing, helps maintain customer trust and ensures a positive brand image.

Applications of the Box Compression Tester

Box Compression Tester Price is utilized across various sectors, including:

- Food and Beverage: Ensuring packaging can endure the stacking and pressure common in storage and transportation.

- Pharmaceuticals: Verifying that packaging is strong enough to protect delicate medical products during shipment.

- E-commerce: As online retail continues to expand, the need for sturdy packaging that can withstand multiple handling points is more important than ever.

- Electronics: Protecting sensitive electronic devices during transport requires packaging with sufficient compressive strength.

Selecting the Right Box Compression Tester

When choosing a Box Compression Tester, several factors should be considered:

- Load Capacity: The tester should be capable of handling the expected loads during testing.

- Precision: Accurate measurements are crucial, especially when packaging must meet stringent industry standards.

- User-Friendly Design: A machine with intuitive controls and features can simplify the testing process.

- Data Management: Advanced models often include software for detailed analysis and reporting of results, making it easier to interpret the data.

Conclusion

Investing in a Box Compression Testing is essential for any manufacturer committed to ensuring the quality and safety of their packaging. By accurately measuring the compressive strength of boxes, this tool helps protect products, optimize material usage, and uphold brand integrity. Whether you're in the food, pharmaceutical, e-commerce, or electronics industry, a Box Compression Tester is a valuable asset for maintaining high standards in packaging.

For more details about Box Compression Testers and their benefits, visit Pacorr Testing Instruments Pvt Ltd, a leader in providing top-tier testing equipment.

Box Compression Tester - Frequently Asked Questions (FAQ)

1. What is a Box Compression Tester?

A Box Compression Tester is a specialized machine used to measure the compressive strength of packaging materials, specifically corrugated boxes and cartons. It determines the maximum load a box can handle before collapsing, providing valuable data for designing durable packaging.

2. Why is box compression testing important?

Box Strength Tester is crucial because it helps ensure that packaging can withstand the pressures of transportation and storage. By knowing the compressive strength of the packaging, manufacturers can prevent product damage, reduce costs, and maintain compliance with industry standards.

3. How does a Box Compression Tester work?

The Box Compression Tester works by placing a box between two plates—one fixed and one movable. The movable plate applies pressure to the box until it collapses. The machine measures the force exerted and records the maximum load the box can withstand before failure.

4. What industries benefit from using a Box Compression Tester?

Various industries, including food and beverage, pharmaceuticals, e-commerce, and electronics, benefit from using a Box Compression Tester Price. These sectors rely on strong, durable packaging to protect their products during shipping and storage.

5. What factors should be considered when selecting a Box Compression Tester?

When choosing a Box Compression Tester, consider the load capacity, accuracy, ease of use, and data analysis capabilities of the machine. Ensuring the tester meets your specific requirements is essential for obtaining reliable results.

6. How does box compression testing contribute to cost efficiency?

By understanding the compressive strength of packaging, manufacturers can optimize material usage, potentially reducing costs without compromising quality. Proper testing ensures that only the necessary amount of material is used, avoiding excess while maintaining product safety.

7. Can a Box Compression Tester help with industry compliance?

Yes, a Box Compression Tester can help ensure that packaging meets specific industry standards for strength and durability. This is important for maintaining compliance with regulations and ensuring the safety of products during transport.

8. What are the common applications of box compression testing?

Box compression testing is commonly used to assess the strength of packaging in various scenarios, such as stacking during storage, handling during shipping, and general product protection. It’s especially critical in industries where packaging integrity directly impacts product quality.

9. How often should packaging be tested with a Box Compression Tester?

The frequency of Box Compression Testing depends on the packaging materials used, the conditions they will face, and industry standards. Regular testing is recommended, especially when introducing new packaging designs or materials, to ensure continued product protection.

10. Where can I purchase a reliable Box Compression Tester?

Reliable Box Compression Testers can be purchased from trusted suppliers like Pacorr Testing Instruments Pvt Ltd. They offer a range of high-quality testing equipment tailored to meet the needs of various industries.